Plastics are used day-to-day, from medical items to household merchandise, offering unmatched versatility. As requires for enhanced efficiency develop, incorporating antimicrobial parts into plastics has grow to be widespread. Nonetheless, questions on sustaining the integrity of the distinctive supplies sometimes come up; will the durability, energy or look be compromised? At BioCote, we assure the reply is a assured no, backed by the info and expertise of our workers and rigorous processes.

Understanding Antimicrobial Parts in Plastics

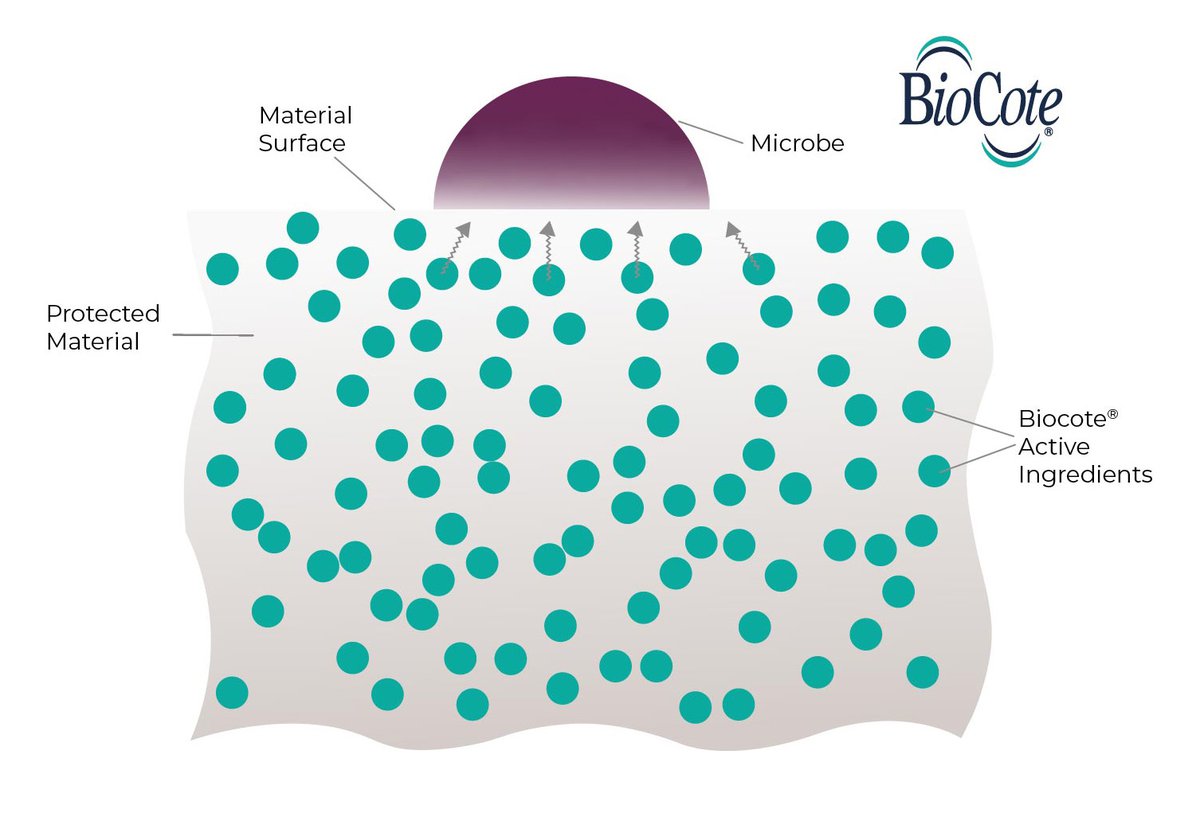

Antimicrobial parts are substances built-in into plastics all through manufacturing to inhibit the growth of microorganisms on the product flooring. These current a long-lasting enhancement to merchandise with out altering their genuine properties. Attaining this steadiness requires a precise understanding of the parts and the plastics.

As David Hall, Managing Director at Biocote, explains, “Not all plastics are created equal. Different types – similar to polyamide, polypropylene, polycarbonate, and PVC – have distinctive chemical compositions, thermal tolerances and mechanical properties. Our technical workers assesses all kinds to seek out out most likely probably the most acceptable additive and software program methodology. Whether or not or not the plastic is injection-moulded, extruded or thermoformed, the mix course of is rigorously tailored to ensure optimum outcomes.”

He continues by explaining that “The strategy begins with selecting an antimicrobial additive that enhances the plastic’s specific properties. This step is crucial to cease any unfavorable interactions between the additive and the polymer. Subsequent, the additive is compounded into the plastic, guaranteeing even distribution. Uneven dispersion may end up in inconsistent effectivity or seen defects, which we mitigate through meticulous prime quality administration.”

Temperature might be necessary. Many plastics are processed at extreme temperatures, which can degrade some parts. Our workers ensures the chosen additive withstands the required heat with out dropping efficacy. As Dr Conner Hodgkiss, Regulatory Chemist, supplies “This technical expertise permits plastics dealt with with BioCote to care for their antimicrobial effectivity all via the product’s lifecycle.”

Broad Functions with Precise Outcomes

From sterile environments like hospitals to widespread residence items, antimicrobial-treated plastics have numerous features. These choices present added value previous efficiency, enhancing product longevity and setting them apart in aggressive markets.

In healthcare, antimicrobial plastics contribute to cleaner surfaces on medical items, whereas in consumer gadgets, they help create brisker devices like kitchen utensils and storage containers. BioCote know-how seamlessly integrates into the manufacturing course of, empowering firms to innovate with out compromise.

At BioCote, we combine scientific precision with commerce notion, guaranteeing antimicrobial parts elevate plastics with out affecting their core qualities. By defending merchandise in opposition to microbes that set off staining, odors and supplies degradation, BioCote helps create longer-lasting merchandise, lowering the need for premature various and contributing to a further sustainable technique to consumption.