In a majority of devices, molders use only one part after the injection part to pack and keep the plastic inside the mould—the so-called keep part. Genuinely, the molder ought to differentiate between the pack and the keep phases. For the sake of simplicity, on this text, we’ll consult with the second part as a result of the keep part and cover the technique of optimization, after which extra differentiate the two inside the second half of this assortment in December.

For cold-runner molds, keep events are optimized by conducting a gate-freeze analysis the place the half weight is recorded as a function of the keep events. When the gate freezes, the half weight stays mounted with rising time. A second or so is added to the underside price of time the place the half weight stays mounted, and this amount is taken as the total time for the setting of keep time.

In hot-runner or valve-gated packages, then once more, the gate house always has molten plastic, and as a result of this reality the part-weight curve in no way flattens. Due to this, the above methodology does not produce acceptable outcomes.

Molders wish to hunt down an optimized combination of keep events and pressures, after which conduct a DOE to optimize the parameters all through the on the market limits.

Excessive keep time and keep stress might trigger defects similar to flash, stress inside the half, and elements staying on the unsuitable aspect of the mould. Inadequate stress, however, might trigger shorts, sinks, and dimensional factors. Molders wish to hunt down an optimized combination of keep events and pressures, after which conduct a DOE (Design of Experiments) to optimize the parameters all through the on the market limits.

Two totally different phrases need clarification. The first is the Magnificence Course of Window (CPW) and the second is Dimensional Course of Window (DPW). CPW refers again to the course of limits inside which cosmetically acceptable elements could also be molded. DPW shows the strategy limits inside which elements could also be molded so that they’re dimensionally acceptable. The DPW is always contained within the CPW.

What follows is the method to optimize keep events for hot-runner and valve-gated molds. It is primarily based totally on a two-cavity show mould used to make elements for the irrigation enterprise.

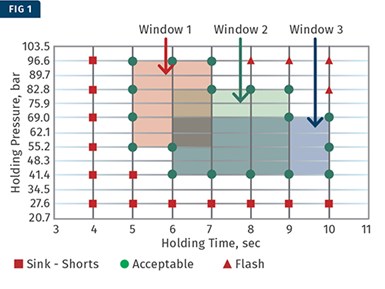

Crimson squares symbolize a element with a defect at lower pressures and events; crimson triangles level out a element with a defect on the higher end of the pressures and events; and inexperienced circles current a element that is cosmetically acceptable.

First, a template to generate a magnificence course of window was prepared. The X-axis corresponds to the holding time and the Y-axis corresponds to the holding stress. Such a template is called a Seen Inspection Template (VIT). A completed VIT is confirmed in Fig. 1. The crimson squares symbolize a element with a defect at lower pressures and events (sink, temporary shot, and so forth.); crimson triangles current a element with a defect on the higher end of the pressures and events (flash, overpacked elements, and so forth.); and inexperienced circles reveal a element that is cosmetically acceptable.

Starting with a keep stress of 27.6 bar (400 psi), elements had been molded from 27.6 bar to 96.6 bar (1400 psi) in steps of 13.8 bar (200 psi) with holding events from 4 to 10 sec in 1-sec increments. The data was collected and recorded inside the VIT. The defect on the lower pressures and events was sink, whereas on the higher aspect, it was flash inside the show house. One can now draw quite a few CPWs inside the VIT.

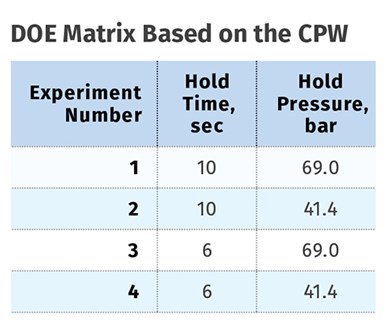

As quickly as these residence home windows are determined, the next step is to seek for dimensions using the DOE methodology. The strategy is numerous between the boundaries of the house home windows and the scale which is perhaps evaluated. After considering the three CPWs and totally different manufacturing requirements, it was decided to pick Window 3 for determining the boundaries of the DOE. The DOE matrix is confirmed inside the accompanying desk.

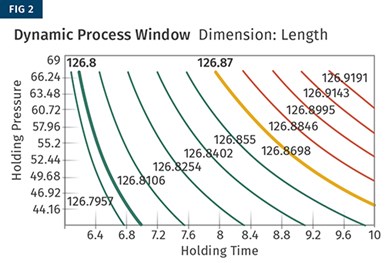

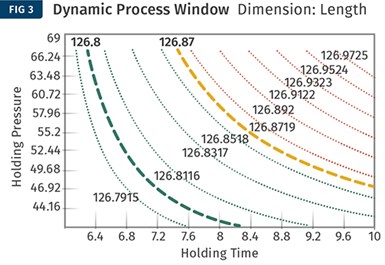

Elements had been molded on the 4 settings indicated inside the desk and had been measured for dimensions. The dimensional requirement on this half was the scale, which was specified at 126.80 ±0.07 mm. The analysis was carried out with the DOE module of the Nautilus Software program program. The outcomes are confirmed in Figs. 2 by 4.

Figures 2 and three current the DPW for cavity one and two, respectively. The steady inexperienced contour traces symbolize cavity one and the dotted contour traces symbolize cavity two. The inexperienced traces symbolize the settings the place the elements are dimensionally acceptable, and the crimson traces symbolize the settings the place the elements are dimensionally not acceptable. The orange traces are the upper specification limits.

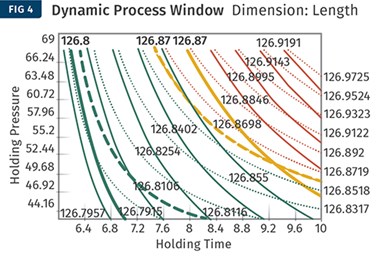

In Figs. 2 & 3 above, the steady inexperienced contour traces symbolize cavity one and the dotted contour traces cavity two. Inexperienced traces symbolize settings the place the elements are dimensionally acceptable, and crimson traces level out settings the place elements are dimensionally unacceptable. Orange traces are the upper spec limits. Proper right here, the two contour plots are overlayed in a combined contour graph. The realm the place the inexperienced contours for each cavity intersect represents settings the place every cavities could also be molded with acceptable dimensions.

Since there are two cavities proper right here, the two contour plots must be overlaid to search out out a combined contour graph as confirmed in Fig. 4. The realm the place the inexperienced contours for each cavity intersect represents the settings the place every cavities could also be molded with acceptable dimensions.

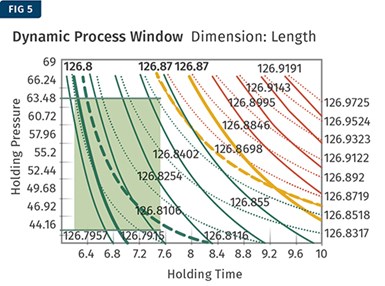

Now it’s possible you’ll draw a composite DPW inside which the elements shall be dimensionally acceptable. Such a window is confirmed in Fig. 5 for the above experimental data. Observing the window, uncover that varied the holding time from 6.2 to 7.5 sec at 43.5 to 63.5 bar will produce dimensionally acceptable elements. Naturally, the bigger this window, the additional robust the strategy goes to be.

It’s a composite DPW, inside which the elements shall be dimensionally acceptable. Uncover that varied the holding time from 6.2 to 7.5 sec between 43.5 to 63.5 bar will produce dimensionally acceptable elements.

Course of robustness is the target of every molder, so it’s most interesting that the center of the DPW in Fig. 5 is used for the strategy settings. A holding stress of 55 bar and a holding time of seven sec had been chosen as the strategy settings. Varied the holding time from 6.2 to 7.5 sec between 43.5 to 63.5 bar will nonetheless produce dimensionally acceptable elements. It is a signal of a sturdy course of and may as a result of this reality produce elements not solely to specs however as well as with improved statistical course of performance. As soon as extra, quite a few DPWs are attainable proper right here. On molding machines, the extent of stress variation is bigger than time variation, and as a result of this reality maximizing the stress window is always hottest.

The above mould had passed by an iteration for steel adjustment, resulting in an appropriate course of window. By way of the primary iteration, the mould could not make elements continually to dimensional specification. The CPW was big, nevertheless the DPW was terribly small. Considering every cavities, the molding course of was not robust. Don’t forget that molding elements to spec does not suggest that each one the elements shall be inside spec; molders wish to know and measure the combined variation inside the machine, supplies, course of, and so forth.

This course of applies to hot-runner molds nevertheless could also be merely extended to valve-gated molds. The method, the reality is, is barely easier as a result of the valve pin shuts off the gate, eliminating the true keep part from the distinctive dialogue of the pack-and-hold part. There are totally different parameters that moreover must be thought-about for the DOE. To take care of points simple, solely two elements and one dimension had been thought-about. Composite dimensional residence home windows for multi-dimensions and cavities must be thought-about.

Optimization of holding-pressure events for hot-runner molds has always been an house of trial and error.

Optimization of holding-pressure events for hot-runner molds has always been an house of trial and error. The method described above is a scientific choice to resolve the holding stress and time in case of scorching runners and valve-gated packages. The method moreover evaluates and demonstrates the robustness of the strategy and the ability to mould elements continually.

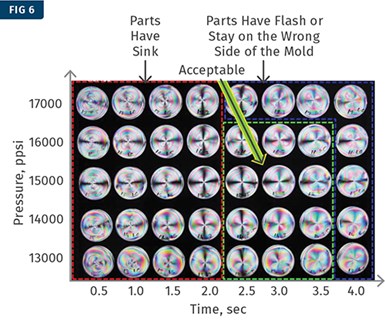

Polarized delicate beneath an optical cowl revealed a sink inside the gate house. A VIT was generated using these images, adopted by a DOE.

An fascinating analysis was achieved using polarized delicate on an optical cowl (see Fig. 6). On this case, the sink inside the gate house was seen beneath polarized delicate. A VIT was generated using these images adopted by a DOE as described above.

Subsequent concern, the primary goal shall be on differentiating between the pack and keep phases for every hot and cold runners.

ABOUT THE AUTHOR: Suhas Kulkarni is the founder and president of Fimmtech, San Diego, an injection molding service-oriented company specializing in Scientific Molding. Fimmtech has developed quite a few custom-made devices that help molders develop robust processes, and its seminars have expert a complete lot of individuals. Kulkarni is an creator of the best-selling information, Sturdy Course of Enchancment and Scientific Molding, revealed by Hanser Publications. Contact: (760) 525–9053; suhas@fimmtech.com; fimmtech.com.